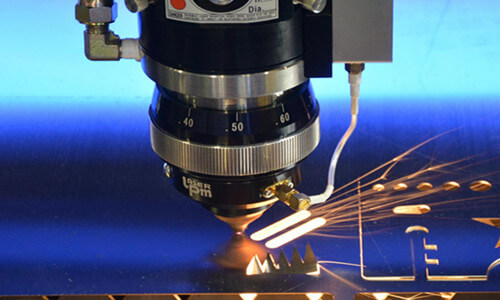

At present, the latest type of cutting machine equipment used in the world is the fiber laser cutting machine. Through the output of the laser beam with high energy density, the laser beam can be focused on the surface of the processed workpiece, so that the materialization of the equipment can be instantaneously achieved. With gasification, the purpose of automatic cutting is achieved. Compared with the gas laser machine, the fiber laser cutting machine has obvious advantages in cutting, and has become the most important first choice equipment in the field of high-precision laser processing.

Fiber laser cutting machine can be used for cutting metal sheet. Either bevel cutting or round tube cutting can achieve very high precision cutting requirements, which can ensure that the cutting edges are more neat and smooth. Moreover, the fiber laser cutting machine has absolute advantages in consumables, working efficiency and environmental protection, so it can be called a leading technology product.

So, how to use fiber laser cutting machine correctly?

1. When using fiber laser cutting machine, be sure to clean its guide rails frequently, wipe the rack of the equipment frequently, and apply lubricant to the guide rails to ensure that there is no debris.

2. The motor ring should also be cleaned frequently, which is conducive to ensuring the operation of the fiber laser cutting machine, and can also be accurately cut to ensure the quality of the cutting product.

3. Every week, the equipment management personnel should suck the dust and debris in the machine through a vacuum cleaner, and ensure that all electrical cabinets should be protected from dust.

Finally, if you want to ensure the service life of the fiber laser cutting machine, you need to check the straightness and verticality of its track every six months. Once it is found to be abnormal, it should be maintained and debugged in time.

CNC machining service is the core business of DO Machining, from protptyes to bulk production, our professional 3/4/5 aixs CNC machining centers, CNC turning equipments, CNC turning-milling equipments, CNC grinding machines etc., are operated by well trained manufacturing engineers to meet the demands from global 1000+ customers in 30+ industries.

CNC Machining can be done starting with blanks produced from standard bar stock or one of DO Machining other manufacturing processes.

Contact us to see how we can provide overall value to your CNC machining needs.