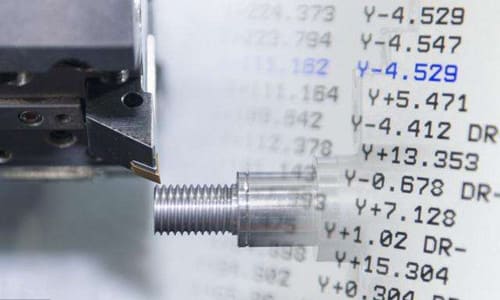

CNC programming is a difficult task for most people. Judging from the current CNC machining market, not all the people engaged in related work are from the industrial mechanical field, but they can still do well in CNC machining work. Of course, this is inseparable from the hard work and efforts of the day after tomorrow. In the process of learning CNC programming, mastering appropriate skills and methods can achieve a multiplier effect.

1. Have your own methodof learning

In fact, everyone’s learning methods and conditions are different. For example, when some people first enter the CNC machining industry, some masters will teach them by hand. In this way, there is a practical opportunity to quickly master the operation and programming of the CNC machining center. Some people read books and learn to master quickly, while others need practice to consolidate. There are many free teaching resources now, choose the right method is very important for learning CNC machining center programming.

2. Diligent in learning and thinking

No matter what method is used, learning is essential. In daily work, if you have any questions, you should consult the master. On some occasions, you can show your own programs, don’t be afraid of making mistakes.

In terms of thinking about problems, if you do n’t have a clue for 15 minutes, you may have a shortcoming in your cognition. At this time, you can tentatively work in progress and ask your colleagues if there is a way to solve the problem. Only in this way can reflect the significance of thinking to CNC machining center programming.

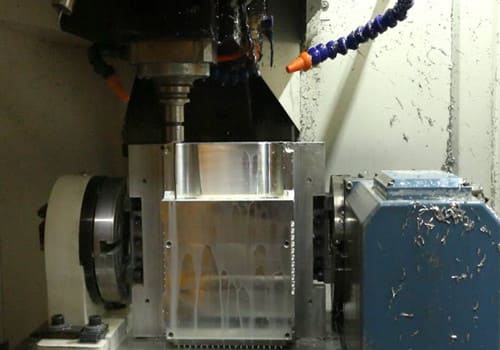

3. Start from the basic operation of CNC machining center

Programming that does not operate the machine is like talking on paper. Only when you actually understand the tooling path, will you have the most suitable tool movement method. This kind of experience cannot be realized without personal experience. Only through hands-on practice can we know what is lacking in the skills. In addition, programming is a skill related to design, which requires inspiration on the basis of rich practical operations.

In recent years, the development of numerical control technology is in a blowout trend. The programming technology is also being upgraded and developed. Continuous learning, thinking, and practicing can better master the technology of CNC machining center programming.

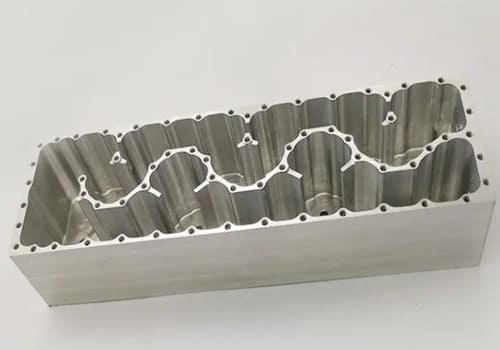

CNC machining service is the core business of DO Machining, from protptyes to bulk production, our professional 3/4/5 aixs CNC machining centers, CNC turning equipments, CNC turning-milling equipments, CNC grinding machines etc., are operated by well trained manufacturing engineers to meet the demands from global 1000+ customers in 30+ industries.

CNC Machining can be done starting with blanks produced from standard bar stock or one of DO Machining other manufacturing processes.

Contact us to see how we can provide overall value to your CNC machining needs.