It is difficult to make deep hole thread on special material parts. For example, deep hole tapping on a titanium part can be very challenging. It is very uneconomical to have the part scrapped due to the scraping action of a broken tap on a near-finished part. Therefore, to avoid scraping, the correct tool and tapping technique are required.

It is first necessary to define what a deep hole is and why it requires special consideration. In drilling, those holes with a depth greater than 3 times the diameter of the hole are called deep holes. And deep hole tapping means that the tapping depth is more than 1.5 times the diameter of the tap. For example, when a 1/4″ diameter tap is used to machine a thread with a depth of 3/8″, this situation is often referred to as deep hole tapping.

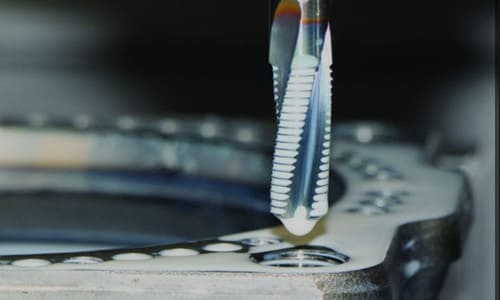

Machining a deep hole thread means prolonged contact between the tool and the workpiece. At the same time, more cutting heat and greater cutting force will be generated during the machining process. Therefore, tapping in small deep holes of special materials (such as titanium parts) is prone to tool breakage and thread inconsistency.

To solve this problem, there are two solutions: 1. Increase the diameter of the hole before tapping; 2. Use a tap designed for deep hole tapping.

1. Increase the diameter of the hole before tapping

Proper bottom hole is very important for threading. A slightly larger threaded bottom hole can effectively reduce the cutting heat and cutting force generated during the tapping process. But it also reduces the contact rate of the thread.

The National Standards and Technology Committee stipulates that in deep holes, only 50% of the full height of the thread is allowed to be tapped on the hole wall. This is especially important when tapping small holes in exotic and difficult-to-machine materials. Because although the thread contact rate is reduced due to the reduction of the thread height on the hole wall, a reliable connection of the thread is maintained due to the increase of the thread length.

The threaded bottom hole diameter increment depends primarily on the required thread contact rate and the number of threads per inch. According to the above two values, the correct threaded bottom hole diameter can be calculated by using the empirical formula.

2. Use a tap designed for deep hole tapping

Since titanium parts are difficult to machine, full consideration of cutting parameters and tool geometry is required.

A. Cutting speed

Due to the large elasticity and deformation rate of titanium alloys, relatively small cutting speeds are required. When machining small holes in titanium alloy parts, the recommended circumferential cutting speed is 10 to 14 inches per minute. We do not recommend using lower speeds, as this will result in work hardening of the workpiece. In addition, it is also necessary to pay attention to the cutting heat caused by the breakage of the tool.

B. Chip flute

When deep hole tapping, the number of tap grooves needs to be reduced to increase the chip space of each groove. In this way, when the tap is retracted, more chips can be taken away, reducing tool breakage caused by chip clogging. On the other hand, the increase in the chip flute of the tap reduces the diameter of the core, so the strength of the tap is affected, which also affects the cutting speed. In addition, helical flute taps are easier to evacuate than straight flute taps.

C. Rake angle and relief angle

A small rake angle increases cutting edge strength, which increases tool life, while a large rake angle is good for cutting long-chipping metals. Therefore, when machining titanium alloys, it is necessary to comprehensively consider these two factors and select the appropriate rake angle.

The large clearance angle reduces friction between the tool and the chip. Therefore, the tap relief angle is sometimes required to be 40°. When machining titanium parts, a large relief angle is ground on the tap, which is conducive to chip removal. In addition, fully ground taps and relief ground taps are also beneficial for tapping.

D. Coolant

When machining special materials, it must be ensured that the cutting fluid reaches the cutting edge. To improve the flow of coolant, it is recommended to open a cooling groove on the back of the tap. If the diameter is large enough, internal cooling taps can be considered.