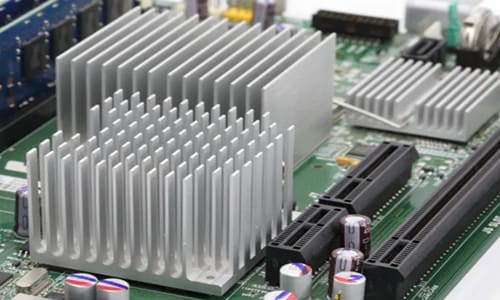

Some people often ask: are the thicker CNC aluminum alloy heat sinks fillets, the better?

Speaking of the heat dissipation effect of the heat sink, the same material, the more the number of heat dissipation fillets of the heat sink, the better, rather than the thickness of the heat sink fillets alone.

The heat sink is used for local or overall heat dissipation of electronic components, and the thickness of the heat sink fillet is determined according to the actual use needs.

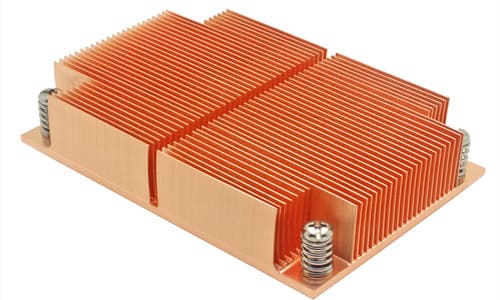

In terms of materials, CNC machined aluminum alloy heat sinks are not as good as copper heat sinks, but aluminum alloys are moderately priced and are high-quality materials for mass customized heat sinks.

In addition, some basic features of CNC customized aluminum alloy heat sink are as follows:

- The anodized aluminum heat sink is resistant to oxidation and will not rust;

- Aluminum has good heat dissipation, light weight and fast heat dissipation.

- It can meet the customized needs. The aluminum alloy heat sink can be machined by CNC into various sizes and structures that meet the needs of its own products to achieve better heat dissipation.

- Aluminum alloy heat sink is suitable for CNC mass production.

The heat dissipation effect of the custom CNC machined heat sink is proportional to the wind receiving surface and inversely proportional to the thickness. Excessive heat dissipation fillets wall thickness cannot guarantee good heat dissipation effect. On the contrary, it will bring excessive material waste and bring unnecessary economic costs to consumers.

Therefore, CNC aluminum alloy heat sink products that meet actual needs can be called good products.