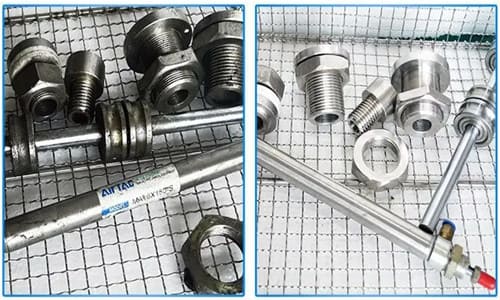

Most construction machinery parts need to be cleaned before, during and after assembly, and some parts are also cleaned after trial operation as needed. So how to clean mechanical parts correctly? Let’s find out together below.

The purpose of cleaning parts is to remove various dirt such as foundry sand, iron filings, rust, abrasives, oil stains, and dust remaining on the surface. The cleanliness of the parts after cleaning will directly affect the assembly quality and the service life of construction machinery, so the cleaning of parts is a very important link in the assembly of construction machinery. To do a good job of cleaning the parts, the cleaning agent and cleaning method should be selected correctly according to their materials, structural characteristics, pollution conditions, and their cleanliness requirements.

Oil stains on construction machinery parts are mainly formed by unsaponifiable oil, dust, impurities, etc. Unsaponifiable oils cannot react with strong alkalis, such as various mineral oils and lubricating oils, which are insoluble in water but soluble in organic solvents. There are two methods of removing such oil stains, chemical and electrochemical; commonly used cleaning solutions are organic solvents, alkaline solutions and chemical cleaning solutions; cleaning methods include manual cleaning and mechanical cleaning.

1. Three cleaning solutions

(1) Organic solvents. The common ones are kerosene, light diesel oil, gasoline, acetone, alcohol and trichlorethylene. Using this method to remove oil can dissolve all kinds of oil. The advantages are no need for heating, easy to use, no damage to metal, and good cleaning effect. The disadvantage is that most of them are flammable, high cost, suitable for precision parts and parts that are not suitable for cleaning with hot alkali solution, such as plastic, nylon, cowhide, felt parts, etc. However, it should be noted that the rubber parts cannot be cleaned with organic solvents.

(2) Alkaline solution. Alkaline solution is an aqueous solution of alkali or alkaline salt. It uses emulsifiers to emulsify unsaponifiable oils to remove oil. It is the most widely used cleaning solution for decontamination.

Emulsification is the formation of extremely small fine particles of one liquid, which are evenly distributed in another liquid. Adding an emulsifier to the alkali solution to form an emulsion can reduce the surface tension and adhesion of the oil film, so that the oil film is broken into tiny oil droplets and will not return to the metal surface to remove oil stains. Commonly used emulsifiers are soap, water glass (sodium silicate), bone glue, gum, triethanolamine, synthetic detergent, etc. It should be noted that different cleaning fluids should be used for cleaning parts of different materials. Alkaline solutions have different degrees of corrosion on metals, especially on aluminum.

When cleaning with alkaline solution, it is generally necessary to heat the solution to 80~90°C. Rinse with hot water after degreasing to remove residual lye on the surface and prevent parts from being corroded.

(3) Chemical cleaning solution. It is an aqueous solution prepared by a chemically synthesized water-based metal cleaning agent. The metal cleaning agent is mainly composed of surfactants and has a strong decontamination ability. In addition, there are some auxiliary agents in the cleaning agent, which can improve or increase the comprehensive performance of the metal cleaning agent such as anti-corrosion, anti-rust, and carbon deposition.

The principle is that the cleaning liquid made of cleaning agent first wets the surface of the parts, and then penetrates into the contact interface between the dirt and the parts, so that the dirt falls off and disperses from the surface of the parts, or dissolves in the cleaning liquid, or forms an emulsion on the surface of the parts to achieve the purpose of cleaning parts.

Common cleaning agents for configuring chemical cleaning liquids include LCX-52 water-based metal cleaning agent, CW metal cleaning agent, JSH high-efficiency metal cleaning agent, D-3 metal cleaning agent, DJ-04 metal cleaning agent, and NJ-841 cleaning agent , 817-C cleaning agent, CJC-8 liquid metal cleaning agent.

The preparation method, concentration, cleaning temperature and heating measures of the above-mentioned cleaning agents must strictly abide by the requirements of their instructions. When cleaning by hand, the temperature should be strictly controlled, and it can be cleaned with a brush or a cloth. If there is serious oil stain or carbon deposit, it can be scrubbed with a wire brush. It should be soaked for a certain period of time before cleaning to meet the needs of wetting and soaking. Cleaning can be divided into rough cleaning and fine cleaning. If the cleaning liquid after cleaning is not seriously oily, you can skim off the floating oil on the upper layer and use it again.

2. Five cleaning methods

A. Scrub. Put the parts into a container with diesel oil, kerosene or other cleaning fluids, scrub with cotton gauze or brush with a brush. This method is simple in operation and simple in equipment, but low in efficiency, and is suitable for small batches of small parts. Under normal circumstances, it is not suitable to use gasoline, because it has fat-dissolving properties, which will damage people’s health and cause fire easily.

B. Boil and wash. Put the prepared solution and the parts to be cleaned into a cleaning pool of appropriate size welded with steel plates, heat it to 80~90°C with a stove under the pool, and boil for 3~5 minutes.

C. Spray cleaning. Spray cleaning fluid with a certain pressure and temperature onto the surface of the parts to remove oil stains. This method has good cleaning effect and high production efficiency, but the equipment is complicated, and it is suitable for cleaning parts with less complicated shapes and serious oil stains on the surface.

D. Vibration cleaning. Put the parts to be cleaned on the cleaning basket or rack of the vibrating cleaning machine, and immerse them in the cleaning solution. The vibration generated by the cleaning machine simulates the artificial rinsing action and the chemical action of the cleaning solution to remove oil.

E. Ultrasonic cleaning. The chemical action of the cleaning solution and the ultrasonic vibration introduced into the cleaning solution work together to remove oil stains.

Note: The cleaning method should be reasonably selected according to the cause and characteristics of the oil pollution to ensure the normal use of the parts, avoid corrosion or damage to the parts caused by cleaning, and prevent pollution of the environment and subsequent contamination of the parts.