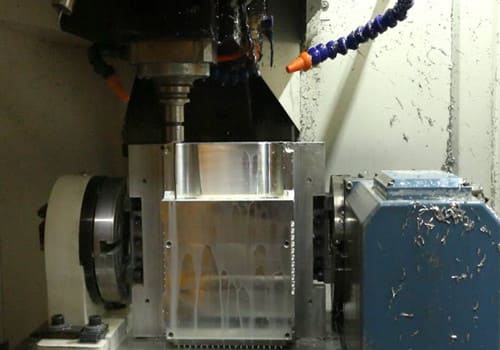

We all know that the precision of CNC machine tools is a very important point, but also one of its advantages, so it is very important to grasp the precision. There’re many factors that can affect the machine tools and machined parts precision, temperature change is one of them. So, what are the effects of temperature changes on the CNC precision parts?

Temperature changes can have several effects on CNC precision parts. Here are some common impacts:

1. Dimensional Changes: CNC precision parts are often made from metal, which expands or contracts with temperature variations. When exposed to higher temperatures, metal parts expand, leading to an increase in their dimensions. Conversely, at lower temperatures, metal contracts, causing a decrease in dimensions. These dimensional changes can affect the overall fit and functionality of the parts, especially in assemblies where tight tolerances are crucial.

2. Material Stress and Deformation: Rapid temperature changes can induce thermal stress in CNC precision parts. If the parts are not able to dissipate or absorb the stress adequately, it can lead to material deformation, warping, or even cracking. This can compromise the structural integrity and functionality of the parts.

3. Machining Tolerances: Temperature fluctuations can impact the machining process itself. CNC machines are designed to operate within certain temperature ranges to maintain accuracy and repeatability. If the ambient temperature deviates significantly from the recommended range, thermal expansion or contraction of the machine components can affect the precision of the machining process. This may result in deviations from the intended dimensions and tolerances of the parts being produced.

4. Surface Finish and Coating Performance: Temperature changes can also affect the surface finish and coating performance of CNC precision parts. For example, extreme heat or cold can cause thermal shock, leading to surface cracks, peeling of coatings, or changes in surface roughness. This can impact the aesthetic appearance, corrosion resistance, or other functional properties of the parts.

5. Assembly and Interchangeability: In situations where CNC precision parts need to be assembled or interchanged, temperature variations can pose challenges. Parts that were machined or stored at different temperatures may have varying dimensions, making it difficult to achieve proper fit and alignment. This can impact the overall performance and reliability of the assembled systems.

To mitigate these effects, manufacturers and engineers often consider factors such as material selection, thermal stabilization techniques, controlled machining environments, and design adjustments to accommodate temperature variations.