In the fast-evolving world of manufacturing, CNC machining stands as a cornerstone technology that has revolutionized production processes. Whether you’re an industry veteran or new to the field, understanding CNC machining is crucial for staying competitive and delivering high-quality products.

What is CNC Machining?

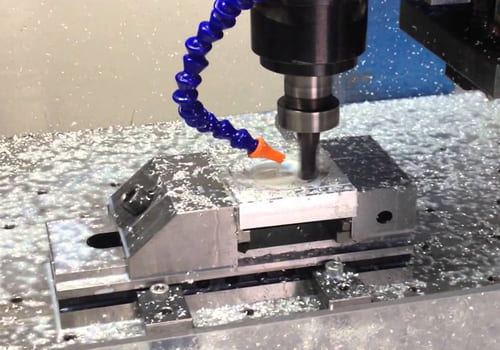

CNC (Computer Numerical Control) machining is a manufacturing process that uses computerized controls and automated tools to remove material from a workpiece, creating precise, custom-designed parts. It is widely used in industries such as automotive, aerospace, electronics, and medical devices due to its versatility and accuracy.

How Does CNC Machining Work?

- Design and Programming: The process begins with a 3D CAD (Computer-Aided Design) model of the part. This design is converted into machine-readable code (G-code) using CAM (Computer-Aided Manufacturing) software.

- Machine Setup: The workpiece is secured on the machine bed, and the necessary tools are loaded into the CNC machine.

- Machining Process: The CNC machine executes the G-code, guiding the cutting tools to remove material and shape the workpiece.

- Quality Control: The final part is inspected to ensure it meets the required specifications and tolerances.

Key Benefits of CNC Machining

- Precision and Accuracy: CNC machines can achieve tolerances as tight as ±0.001 inches, ensuring parts meet exact specifications.

- Efficiency: CNC machining significantly reduces production times compared to manual machining.

- Versatility: Capable of working with a wide range of materials, including metals, plastics, and composites.

- Consistency: Automated processes ensure uniformity across high-volume production runs.

- Cost-Effectiveness: Reduces material waste and the need for extensive manual labor.

Common CNC Machining Processes

CNC machining encompasses various techniques, each suited for different applications:

- CNC Milling: Removes material using rotating cutting tools.

- CNC Turning: Shapes cylindrical parts using a lathe.

- CNC Drilling: Creates precise holes in the workpiece.

- CNC Grinding: Produces a high-quality surface finish.

- CNC EDM (Electrical Discharge Machining): Uses electrical sparks to shape hard materials.

Applications of CNC Machining

CNC machining is integral to many industries, including:

- Automotive: Engine components, custom parts, and prototypes.

- Aerospace: Precision parts for aircraft and spacecraft.

- Electronics: Miniaturized components with tight tolerances.

- Medical Devices: Surgical tools, implants, and equipment.

The Future of CNC Machining

The integration of AI, automation, and IoT (Internet of Things) is shaping the future of CNC machining. These advancements enable predictive maintenance, real-time monitoring, and smarter manufacturing processes, pushing efficiency and precision to new heights.

Conclusion

CNC machining is a cornerstone of modern manufacturing, offering unmatched precision, efficiency, and versatility. By understanding its processes, benefits, and applications, manufacturers can harness this technology to produce high-quality parts and stay ahead in a competitive market.

Ready to explore CNC machining for your manufacturing needs? Contact us today to learn how our cutting-edge CNC solutions can help you achieve your goals.