FRP is a thermosetting plastic product with epoxy resin as binder, glass fiber as filler and small amount of compounding agent. Its density is small and its specific strength is high. The main component is silicon oxide, which is formed by high-speed melting of glass after high-temperature melting, and its hardness and strength are high. In particular, high silica glass reinforced plastics with a silica content of more than 90% have abrasive properties during cutting and cause severe tool wear. Below we will specifically introduce the machining method of FRP.

1. FRP Properties

A. Mechanical properties: The mechanical properties of FRP are outstanding. The specific strength is high, which is incomparable with metal materials and other materials. The lightweight and high-strength properties of FRP are derived from the lower resin density and the high tensile strength of glass fibers.

B. Physical properties: FRP has low density, good electrical insulation performance, thermal insulation performance, water absorption resistance and thermal expansion resistance.

C. electrical properties: FRP has excellent electrical insulation properties, can be used as insulation components in instruments, motors and electrical appliances, still maintain good dielectric properties under high frequency.

D. heat resistance: FRP has good heat resistance, and its specific heat is large. The thermal conductivity is relatively low.

E. anti-aging performance: FRP under the effect of atmospheric exposure, damp heat, water soaking and corrosive medium, the performance has decreased, in the long-term use process will cause gloss loss, color change, resin shedding, fiber exposure, stratification, etc.

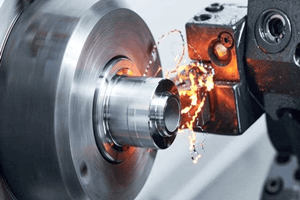

2. Tool

Hard alloys such as YG8, YG6, YG6X, YG3, YG3X, YW1, and YW2 are often used for machining FRP. Under the possible conditions, it is best to use artificial polycrystalline diamond conforming sheet or cubic boron nitride composite sheet cutter, which not only greatly improves the cutting speed, but also improves the tool durability by several dozen times than the hard alloy. Since FRP is mostly brittle material, its elastic modulus is small and the elasticity is restored. In order to improve the heat dissipation condition, the cutting ability of the cutting edge is increased, and the cutting is light.

3. Problems needing attention when processing FRP

A. FRP powder is irritating to human skin. It should be protected against dust and protect the personal safety of workers.

B. in order to prevent the phenomenon of slag falling from the cut-off point, on the one hand, reduce the feed amount at the cut-in and cut-out, on the other hand, first cut the 45-degree angle with the turning tool at the cut-in and cut-out; the turning tool of the thread, a larger rake angle of -10° to -15° should be used to ensure complete tooth shape.