Why Should The Cutting Tool Be Deliberately Passivated?

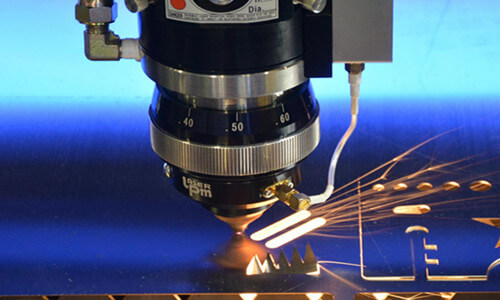

Isn't the cutting tool used in the machining center as fast as possible? Why need to passivate it? In fact, cutting tool passivation is not a literal meaning to everyone, but a way to increase the service life of the tool. Improve tool quality through smoothing, polishing, deburring and other processes. This is [...]