How To Carry Out Plane Machining And Three-dimensional Machining In Machining Center?

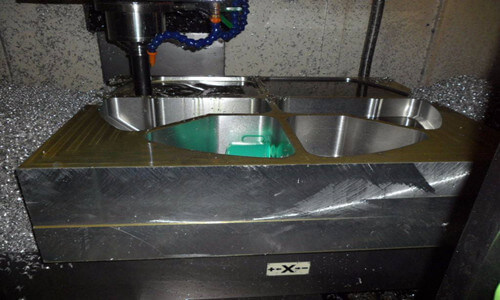

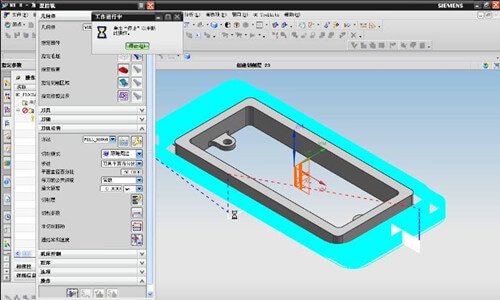

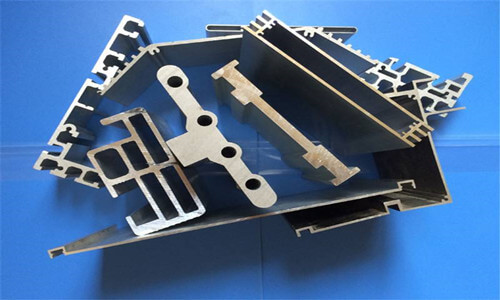

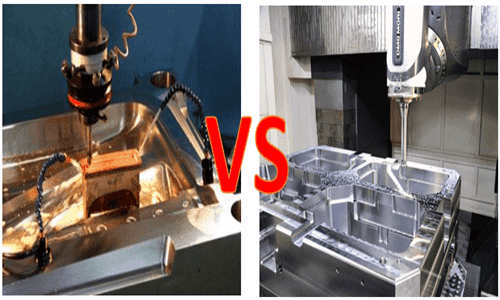

The plane machining with CNC machining center refers to the milling, drilling, reaming, boring and other machining processes on the plane workpiece; the three-dimensional machining refers to the processing of the solid surface under the control of the interpolation function of the CNC system of the machining center. The machining objects include complex curved [...]