How To Be Considered Familiar With Machining Technology?

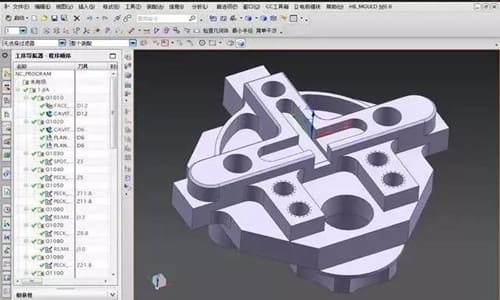

Machining refers to the process of changing the size or performance of a workpiece through a mechanical device. According to the difference in processing methods, it can be divided into cutting processing and pressure processing. For operators or technicians, how can they be considered familiar with the machining process? 1. Understand [...]