When deciding how to manufacture parts for your business, one of the biggest decisions you’ll face is whether to opt for custom CNC machining or mass production. Both methods offer distinct advantages depending on your product requirements, budget, and production timeline. Understanding the differences between the two can help you make an informed decision that best suits your business needs.

In this blog, we’ll explore the pros and cons of custom CNC machining and mass production, and how to choose the right method for your business.

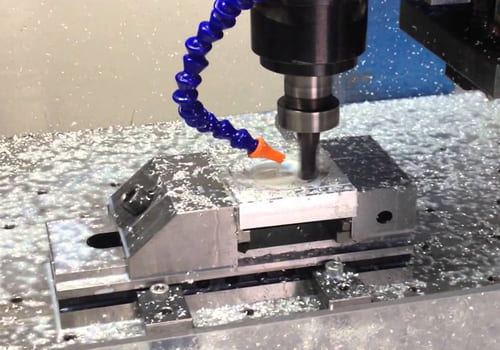

What Is Custom CNC Machining?

Custom CNC machining refers to the process of using computer-controlled machines (like CNC mills and lathes) to produce unique, often one-off parts based on specific design specifications. CNC machines operate by removing material from a solid block or billet, shaping it into the desired form.

Pros of Custom CNC Machining:

-

High Precision: CNC machining is known for its accuracy, allowing for parts with tight tolerances and complex geometries. This makes it ideal for industries requiring precision, such as aerospace, medical devices, and automotive.

-

Flexibility: Custom CNC machining allows for the production of unique parts tailored to your exact design specifications. If your parts require intricate designs or need modifications along the way, CNC machining can accommodate these changes quickly.

-

Material Variety: CNC machining works with a wide range of materials, from metals like aluminum, stainless steel, and titanium, to plastics and composites. This versatility makes it suitable for many industries and applications.

-

Prototyping: CNC machining is an excellent choice for prototyping because it allows you to produce functional parts quickly and accurately. This is particularly useful for testing designs before committing to large-scale production.

Cons of Custom CNC Machining:

-

Higher Costs for Low Volumes: While CNC machining is cost-effective for prototyping and small-batch production, it may be more expensive for large quantities due to high setup costs, tooling, and labor requirements.

-

Longer Lead Times: Custom CNC machining can sometimes have longer lead times compared to mass production methods, especially for complex parts that require significant setup or specialized tooling.

What Is Mass Production?

Mass production is the process of manufacturing large quantities of standardized parts using automated machines or assembly lines. Unlike custom CNC machining, mass production focuses on producing high volumes of identical parts at lower costs.

Pros of Mass Production:

-

Lower Per-Unit Cost: Once the initial setup is completed, mass production benefits from economies of scale, significantly reducing the cost per unit. The more parts you produce, the lower the cost per part becomes.

-

Fast Production: Mass production is designed for speed, making it ideal for producing high quantities of the same part in a short amount of time.

-

Consistency: Since the same processes are repeated throughout production, mass production offers high consistency in part quality, ensuring that each piece meets the same specifications.

-

Automation: Automation in mass production reduces the need for manual labor, decreasing human error and improving overall efficiency.

Cons of Mass Production:

-

Limited Flexibility: Mass production is optimized for producing large quantities of the same part. If you need to make changes to the design or require custom modifications, mass production may not be the best choice.

-

High Initial Investment: Setting up a mass production line requires a significant upfront investment in tooling, machines, and molds, which may not be viable for small batches or short runs.

-

Longer Setup Times: The setup phase for mass production can take a considerable amount of time, especially if custom molds or dies are needed for the parts.

How to Choose the Right Option for Your Business

1. Consider Production Volume

If you only need a small number of parts or one-off custom components, custom CNC machining is likely the best option. CNC machining is ideal for prototypes, low-volume production, or parts with intricate designs. On the other hand, if you need to produce high volumes of the same part, mass production may be more cost-effective, as it can take advantage of economies of scale.

2. Think About Part Complexity

For parts with complex geometries, tight tolerances, or unique features, custom CNC machining is the way to go. CNC machining allows for a high degree of precision and flexibility, making it ideal for parts that mass production methods may struggle to replicate. However, if your part design is relatively simple and standardized, mass production can handle it efficiently at a lower cost.

3. Assess Lead Times

If you have a tight deadline or need parts quickly, CNC machining may take longer due to setup and tooling requirements. Mass production, on the other hand, offers faster production for large quantities once the setup is complete. Consider your time frame and how quickly you need to scale your production.

4. Evaluate Your Budget

While mass production reduces costs per part in high volumes, custom CNC machining offers more control over the final product, especially for prototypes or low-run custom parts. If you need high-quality parts in small quantities, CNC machining can provide the flexibility and precision you require, even if the per-unit cost is higher. However, for large quantities of standardized parts, mass production offers significant cost savings.

5. Long-Term Needs and Scalability

If you anticipate needing a large volume of parts regularly, mass production may be the best long-term investment. Once the production line is set up, producing thousands or millions of parts is more efficient and cost-effective. For smaller or variable runs, custom CNC machining provides flexibility and adaptability.

Conclusion: Custom CNC Machining vs. Mass Production

Ultimately, the choice between custom CNC machining and mass production depends on your business’s needs, budget, and timeline. If your project requires complex, high-precision parts or rapid prototyping, CNC machining is the best choice. However, if you need high volumes of identical parts with a quick turnaround, mass production may be more suitable.

At domachining.com, we specialize in both custom CNC machining and mass production services. Whether you need a few prototypes or thousands of parts, we have the capabilities to deliver high-quality solutions tailored to your specific requirements. Contact us today to discuss your project and find out how we can help you choose the right manufacturing method for your business.