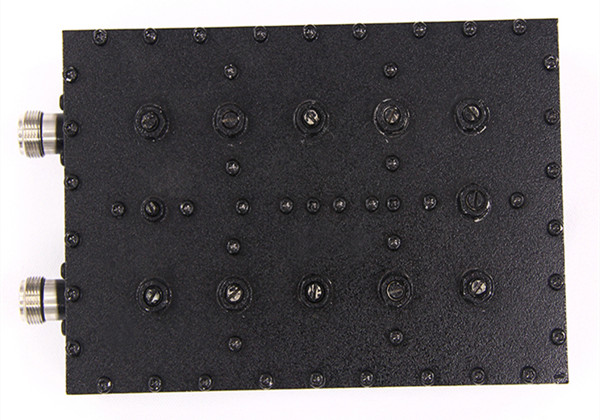

High Pass Band Stop Low Pass Active Power RF Filter Precision Parts Manufacturers

Manufacturing Technology: CNC Milling, CNC Machining.

Industry: RF Filter.

Material: Aluminium 6061 T6.

Surface Finish: Black Anodize.

* Please kindly note we do custom parts manufacturing only, all the products shown in the pictures are for quality reference only but not for sell. If you have any part needing custom manufacturing, please just let us know. Thank you! *

Product Details

This is a custom made High Pass Band Stop Low Pass Active Power RF Filter Precision Parts.

Material: aluminum 6061- T6,

Surface finish: black anodize,

Process: CNC milling, assembling

What is RF filter?

In recent years, with the rapid development of science and technology, wireless communication systems have also made great progress in the rapid development of microwave and millimeter wave technologies. A filter is a typical frequency selection device. It can effectively suppress unwanted signals and prevent them from passing through the filter. Only useful signals pass through the filter smoothly. Therefore, the performance of the filter directly affects the overall communication system Quality, filters are one of the most important devices in modern microwave and millimeter wave communication systems. Wireless communication systems can work in a wide range of frequencies, from tens of MHZ low frequency bands to tens of GHZ high frequency bands. Therefore, in the frequency range in which the wireless communication system operates, many different kinds of filters can be used. And with the increasingly complex electromagnetic environment, microwave filters with higher performance requirements are required.

CNC milling processing is one kind of our most experienced machining processing. It can process the parts with very complex shape and difficult to control size. It even can process the part with complex curves and three- dimension curved surface parts. And it also can reach high precision requirement.

Our CNC milling process produces custom prototypes and end-use production parts as your required. We use 3-axis, 4-axis and 5-axis milling processes to manufacture parts from more than 20 different materials from woods, plastics to metals.

100% Quality Assurance program taken by best-in-class inspection equipment, rigorous QC team and meticulous QC process. Material analysis report and component quality testing report as per customer’s specific requirements.

That’s why we can meet the demands from global 1000+ customers in 30+ industries.

Contact us to see how we can provide overall value to your CNC machining needs. Or send your RFQs to sales@domachining.com directly, PDF drawings, step, iges, dxf and dwg files are all available for us.