Choosing the materials to be used from a variety of materials is a job restricted by many factors. Therefore, how to choose the materials of parts is an important part of parts design. The principle of choosing mechanical parts materials is: the required materials should meet the use requirements of the parts and have good processability and economy.

1. Use requirements

The use requirements of mechanical parts are as follows:

A. The working conditions and loading conditions of the parts and the requirements for avoiding the corresponding failure modes.

The working condition refers to the environmental characteristics of the parts, the working temperature and the degree of friction and wear. The materials of parts working in hot and humid environment or corrosive medium should have good rust and corrosion resistance. In this case, we can consider to use stainless steel, copper alloy, etc. There are two main aspects of the influence of working temperature on material selection: on the one hand, it should be considered that the linear expansion coefficients of the materials of the two parts that cooperate with each other should not be too different, so as not to cause excessive thermal stress or make the fit loose when the temperature changes; On the other hand, it is also necessary to consider the change of the mechanical properties of the material with temperature. For parts working under sliding friction, to increase the surface hardness to enhance wear resistance, we can select hardened steel, carburizing steel, nitrided steel and other varieties suitable for surface treatment, or materials with good wear resistance.

The loading condition refers to the magnitude and nature of the load and stress on the part. In principle, brittle materials are only suitable for the manufacture of parts that work under static loads; in the case of impact, we can choose plastic materials as the main material; for parts whose surface is subject to large contact stress, we can choose the material that can make surface treatment, such as case-hardened steel; for parts subject to strain, we can choose fatigue-resistant materials; for parts subject to impact loads, we can choose materials with high impact toughness; for parts whose size depends on strength but whose size and mass are limited, we can choose materials with higher strength; for parts whose size depends on stiffness, we can choose materials with higher elastic modulus.

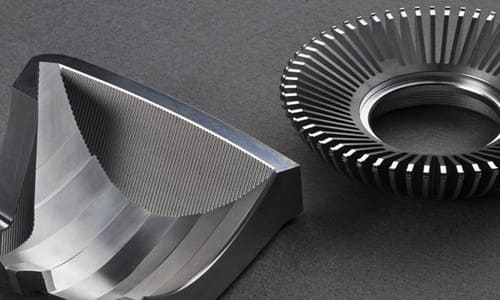

The performance of metal materials can generally be improved and improved by heat treatment. Therefore, it is necessary to make full use of the means of heat treatment to develop the potential of the material; for the most commonly used tempered steel, blanks with different mechanical properties can be obtained due to different tempering temperatures. The higher the tempering temperature, the lower the hardness and stiffness of the material, and the better the plasticity. Therefore, when selecting the type of material, we should specify its heat treatment specification at the same time, and indicate on the drawing.

B. Limitations on part size and quality.

The size and quality of the parts are related to the type of material and the manufacturing method of the blank. When producing casting blanks, it is generally not limited by size and quality; while producing forging blanks, it is necessary to pay attention to the production capacity of forging machinery and equipment. In addition, the size and quality of the parts are also related to the strength-to-weight ratio of the material. We should choose materials with a high strength-to-weight ratio as much as possible to reduce the size and quality of the parts.

C. The importance of parts in the whole machine.

D. Other special requirements (such as whether insulation, anti-magnetic, etcis required).

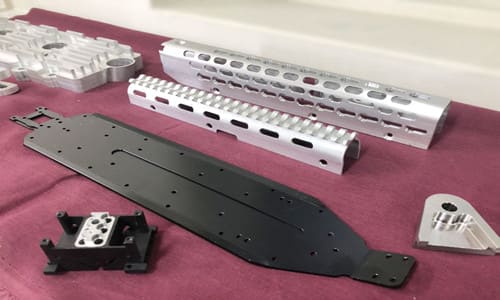

2. Process requirements

In order to make the parts easy to process and manufacture, we should the complexity of the part structure, size and blank type when choosing materials. For parts with complex shapes and large sizes, if casting blanks are considered, we should choose materials with good casting performance; if welding blanks are considered, we should choose low-carbon steel with good welding performance. For parts with simple shape, small size and large batch size, suitable for stamping and die forging, we should choose materials with better plasticity. For parts requiring heat treatment, the material should have good heat treatment properties. In addition, we should also consider the ease of processing of the material itself and the ease of processing after heat treatment.

3. Economic requirements

A. The relative price of the material itself

Under the premise of meeting the requirements of use, we should choose materials with low price as much as possible. This is especially important for parts manufactured in high volumes.

B. Processing costs of materials

When the quality requirements of the parts are not high and the processing volume is large, the processing cost will account for a large proportion of the total cost of the parts. Although cast iron is cheaper than steel plates, for some single-piece or small-batch production box parts, the cost of welding with cast iron is higher than that of steel plates, because steel plates can save the cost of mold manufacturing.

C. Saving material

In order to save materials, we can use heat treatment or surface strengthening (shot peening, rolling, etc.) to fully develop and utilize the potential mechanical properties of materials; We can also use surface coating (chrome plating, copper plating, blackening, French blue, etc.) to reduce the degree of corrosion and wear, prolong the service life of parts.

D. Utilization of materials

In order to improve the utilization rate of materials, we can use non-cutting or less cutting processing, such as die forging, precision casting, stamping, etc., which can not only improve the utilization rate of materials, but also reduce the working hours of cutting processing.

E. Save valuable materials

By adopting a combined structure, we can save expensive materials. For example, the worm gear ring gear of the combined structure adopts tin bronze with better anti-friction but expensive price, while the wheel core adopts cheap cast iron.

F. Save rare materials

In this regard, we can use manganese-boron series alloy steel instead of chromium-nickel alloy steel with less resources, and use aluminum bronze instead of tin bronze.

G. Availability of materials

When chooseing materials, we should choose materials that are locally available and easy to supply to reduce the cost of procurement, transportation, and storage; from the perspective of simplifying the supply and storage of material varieties, for parts produced in small batches, the variety and specifications of materials used on the same machine should be minimized to simplify supply and management, thereby improving manufacturing quality, reducing waste products, and increasing labor productivity.