Effective communication is crucial when working with a CNC machining partner. Whether you’re creating custom parts, prototyping new products, or scaling up production, clear communication ensures that both parties are aligned, reducing misunderstandings, delays, and errors. In this blog, we’ll discuss the best practices to improve communication with your CNC machining partner, helping you achieve smoother workflows, higher quality parts, and better business outcomes.

1. Define Clear Project Goals and Expectations

The foundation of effective communication starts with defining clear goals and expectations from the outset. Be sure to communicate the specific requirements of your project in detail. This includes:

- Part specifications: Material type, dimensions, tolerances, and surface finishes.

- Production timeline: Lead times, deadlines, and milestones.

- Volume requirements: Are you ordering a prototype, a small batch, or high-volume production?

- Quality standards: Any specific certifications, inspection requirements, or regulatory compliance.

Why This Matters:

Having clear, documented specifications from the start ensures both parties understand what’s expected, which reduces the likelihood of errors and ensures timely delivery of parts.

2. Establish Open and Regular Communication Channels

Choose a communication channel that works best for both parties—whether it’s email, phone calls, or project management software. Regular updates are essential, especially for ongoing projects or complex orders.

- Set up a regular check-in schedule: Weekly or bi-weekly updates can keep both teams informed about project progress, any potential delays, or issues.

- Be responsive: Replying to emails or calls promptly ensures that issues are resolved quickly and doesn’t delay the production timeline.

- Use collaborative tools: Tools like Slack, Asana, or Trello can help streamline communication, especially for larger projects that require input from multiple stakeholders.

Why This Matters:

Regular communication helps ensure both you and your CNC partner are on the same page and can address any potential issues before they become bigger problems.

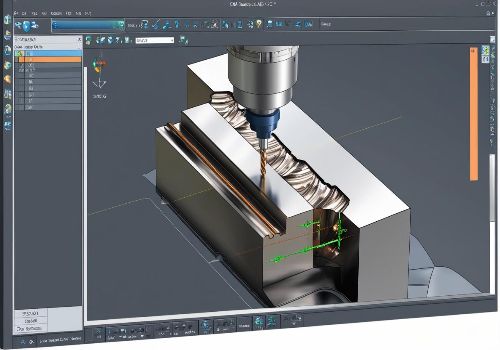

3. Share Complete and Accurate Design Files

One of the biggest challenges in CNC machining is ensuring that the design files provided to the supplier are complete and accurate. To avoid delays or misunderstandings:

- Use standardized file formats: Ensure your design files are in commonly accepted formats like STEP, IGES, or STL, which can easily be interpreted by CNC machining software.

- Provide detailed drawings: Along with CAD files, include any relevant drawings, specifications, and notes that outline critical aspects of the design.

- Use 3D models for complex designs: This provides a clearer understanding of your expectations for more intricate or complex parts.

Why This Matters:

Providing clear and complete design files helps your CNC machining partner understand your vision, reduces the chance of errors during production, and improves overall quality.

4. Ask for Regular Progress Updates and Prototypes

If you’re working on custom parts or prototypes, it’s important to request regular updates or prototypes throughout the process. This allows you to:

- Monitor progress: Check the accuracy of initial parts and ensure they meet your requirements.

- Identify issues early: If any discrepancies arise, they can be addressed before proceeding with full-scale production.

- Test fit and functionality: Prototypes allow you to verify the part’s fit and functionality before investing in larger quantities.

Why This Matters:

Prototypes and progress updates provide an opportunity to identify issues early, making it easier to make adjustments without incurring significant costs.

5. Encourage Feedback and Open Dialogue

Establish a culture of feedback and collaboration with your CNC machining partner. Encourage them to provide their expert insights on your designs, materials, or manufacturing processes. CNC machinists may suggest design improvements or more cost-effective material choices that can improve both the quality and cost of the final product.

- Be open to suggestions: Machinists and engineers may have valuable input based on their experience, which can help optimize your designs for production.

- Provide constructive feedback: If the parts are not as expected, explain clearly where things went wrong and work with your partner to find solutions.

Why This Matters:

Encouraging open dialogue and feedback strengthens your relationship with your CNC machining partner and can lead to improved designs, optimized production processes, and better overall outcomes.

6. Clarify the Pricing Structure

Understanding how your CNC machining partner prices their services is essential for managing costs. Make sure to discuss the following:

- Material costs: Understand how material choices affect pricing.

- Setup fees: Determine if there are any setup charges for tooling, programming, or initial setup.

- Post-processing costs: Confirm whether finishing, coating, or additional processes are included in the quote or charged separately.

Why This Matters:

Clear pricing ensures that both parties are aware of any potential costs upfront, preventing unpleasant surprises when you receive the final invoice.

7. Set Realistic Expectations for Lead Times

One common source of frustration between businesses and their CNC machining partners is missed deadlines. To prevent this, ensure that both parties agree on the lead times from the beginning of the project.

- Set realistic expectations: Take into account machine availability, material procurement, and potential delays.

- Factor in the complexity of the part: More intricate designs may take longer to manufacture.

- Account for shipping and delivery: Don’t forget to include the time required for packaging and shipping the parts.

Why This Matters:

Setting clear expectations for lead times helps manage project timelines and ensures that your parts arrive when you need them, avoiding costly delays.

8. Understand the Supplier’s Quality Control Process

Quality control (QC) is crucial for ensuring the final parts meet your specifications. Ask your CNC machining partner about their QC processes, including:

- Inspection tools: Do they use advanced tools like CMMs (Coordinate Measuring Machines) or laser scanners to check for accuracy?

- Frequency of inspections: How often do they inspect parts during production?

- Documentation: Will they provide you with inspection reports and certificates of conformity?

Why This Matters:

A strong QC process ensures that the parts you receive are accurate and meet the necessary tolerances, reducing the need for rework or returns.

9. Maintain a Long-Term Partnership

Finally, consider fostering a long-term relationship with your CNC machining partner. Long-term partnerships are built on trust, mutual respect, and a shared commitment to quality and performance.

- Consistent orders: If your CNC machining partner understands your business needs over time, they can better anticipate future requirements and optimize production.

- Volume discounts: Long-term relationships may lead to better pricing, faster turnaround times, and priority service.

Why This Matters:

A long-term partnership creates a reliable workflow, enabling both you and your CNC machining partner to optimize processes and reduce costs over time.

Conclusion

Effective communication with your CNC machining partner is the key to achieving high-quality parts, meeting deadlines, and optimizing production efficiency. By following these best practices—defining clear goals, maintaining regular communication, and fostering a strong partnership—you can ensure that your machining projects run smoothly and deliver the results you need.

At domachining.com, we value collaboration and clear communication with our clients. We specialize in high-precision CNC machining, offering tailored solutions that meet your specific needs. Contact us today to discuss your project and learn how we can help you achieve seamless, high-quality production.