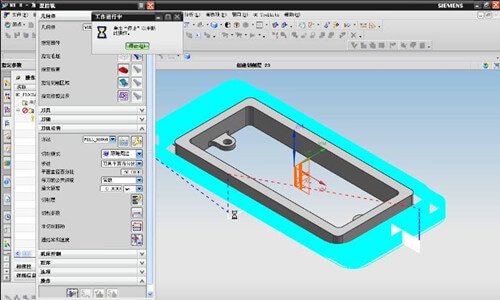

In the CNC machining process, an important part of the process preparation is the planning of the tool path. The tool path refers to the trajectory of the tool relative to the workpiece. The purpose of the plan is to better avoid the interference between the tool and the workpiece. Whether the path planning is reasonable will directly affect the accuracy and efficiency of CNC machining. To this end, the technician can achieve this by optimizing the tool shape and optimizing the tool path algorithm.

Optimize tool shape

If the tool shape is different, the interference position and interference judgment will be different. Therefore, by properly optimizing the tool shape and the distribution of the cutting portion, the interference of the tool can be largely avoided. When machining complex workpieces, especially complex composite molds, it is especially important to select tools of different shapes and to optimize too shape to avoid tool and workpiece interference, to ensure cutting quality and efficiency.

Optimize tool path algorithm

In addition to optimizing the tool shape, the actual point of contact between the tool and the workpiece must be calculated and the position of the tool location determined in conjunction with the tool shape so that a reasonable tool path can be planned. The methods for optimizing the tool path algorithm mainly include Isoparametric method, the equidistant cross section method, the equal residual height method and the projection method.

The isoparametric method is an algorithm based on the original surface parameter path. Since most of the surfaces being machined have fixed surface parameters, you can borrow these parameters to get the machining path. This method is relatively simple, so it is widely used. However, the path generated by the original parameters is not absolutely applicable to the actual machining. The tool path in the narrow part of the surface may be too complex, and in the wide part of the surface is too simple, machining accuracy can not be guaranteed.

The equidistant cross section method includes CL and CC. CL path cross section method takes the intersecting line formed by two machining surfaces as the tool path. CC path cross section method takes the contact between tool and workpiece as the path of another surface. Compared them, CC method is easier to control the tool path during machining, and the tool path is also evenly distributed. Especially for complicated surface with uneven parameter distribution, CC method has higher machining efficiency, but its disadvantage is complicated calculation and large calculation.

The residual height method is an algorithm that keeps the residual height of its motion trajectory unchanged during the movement of the tool. The key to the realization of this algorithm is to control the distance between adjacent motion trajectories to keep the residual height stable. This algorithm can keep the force of the tool evenly, and it can easily calculate the subsequent tool path under the current tool path condition, and the calculation amount is small. However, when the workpiece surface parameters are unstable, it may affect the cutting efficiency.

The tool path calculated by projection method is the projection along the guide curve on the workpiece surface. This method is applicable to machining parts with special curved surfaces, especially in the case of collision interference.

Because the direction of each contact point is different on such a workpiece surface, tool interference is less likely to occur and the tool path can be more effectively controlled.