Do you know some basic knowledge of mechanical processing? Such as common equipment, processing procedures, production types and precautions?

Here we’d like to briefly introduce some knowledge, so that you can have a greater understanding of large-scale mechanical processing.

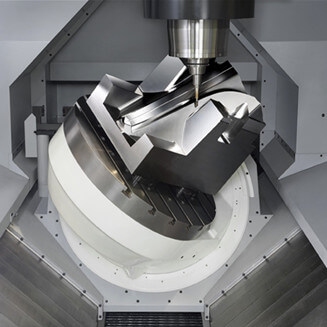

1. Mechanical processing of the common equipment

Including cnc milling machine, cnc molding grinder, cnc lathe machine, EDM machine, universal grinding machine, cylindrical grinding machine, internal grinding machine, precision lathe and other equipment, these equipment can do turning, milling, planing, grinding and other processes. The processing accuracy can up to 2um.

2. Manufacturingprocedure of processing

The production processes includes the transportation of raw materials, the preparation of production, the workblank manufacturing, the parts processing and heat treatment, the parts assembling and debugging. Through mechanical processing, it can change the shape of raw materials, size and performance, and meet the requirements.

3. Processing type

Single piece processing: the production of a single part, rarely repeated production.

Batch processing: Batch manufacturing the same parts.

Bulk processing: When the product is manufactured in great quantities, it is necessary to repeat the production of one part frequently.

When choosing the processing, because parts processing types are different, the production methods, equipment, tools, workblanks and technical requirements are different as well.

4. Precautions of processing

a. to facilitate the processing operation, to minimize unnecessary bending, tiptoe action.

b. positioning should be accurate and reliable, to prevent vibration, resulting in error.

c. the direction of movement of the device operating parts and the direction of movement of the manipulated parts shall meet the specified requirements and shall be clearly marked.

d. set the necessary interlock mechanism to prevent unacceptable action in the operation, causing danger.

e. axis, hand wheel, button structure and arrangement to meet the requirements. General start button should be installed inside the case, and install protective rings that prevent accidental touching, the shaft should be equipped with automatic prolapse device to prevent hand wheel, handle wounding.

Note: Above information is just for reference only.

We offer CNC Machining, Metal Stamping, Metal fabrication services, if you have project need support, contact us today.