The mold manufacturing process is a complex process. From design, processing, assembly, commissioning to final real use, there are many factors affecting the quality of the mold throughout the life cycle, which requires the attention of the operator during the processing.

What are the reasons that affect the quality of the mold?

1. Mold steel

Steel is the decisive factor in the quality of the mold, and choosing the right steel is the top priority. The criteria for choosing steel are:

Requirements for injection molding materials– Different plastics should be made of different steels, such as high polishing requirements, corrosion resistance requirements, etc.

Price- Steel properties are good enough, not the more expensive the better; considering the cost of the mold, the mold steel should use the material corresponding to the life of the mold to avoid unnecessary waste.

Heat Treatment- The surface treatment of the mold is also very important.

Nitriding – can enhance the surface hardness of steel and effectively extend the life of the mold;

Electroplating- can effectively modify the mold steel, for some high-brightness and corrosion-resistant plastic parts can use electroplating to enhance and improve the performance of steel.

2. Structural design

The mature mold structure not only takes into account the material properties of the product – shrinkage rate, molding temperature, elastic tensile deformation coefficient, etc., but also considers the cooling water passage, the speed of opening and closing the mold, and the like. Reasonable mold structure can effectively extend the life of the mold and ensure the smooth production of the mold. Improve efficiency and reduce costs.

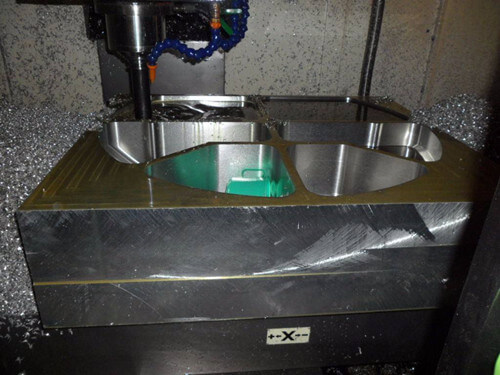

3. Mold processing

The arrangement of the mold process is particularly important, and the reasonable process arrangement can speed up the production cycle, shorten the processing time, and effectively save costs. And more importantly, accurate and reasonable processing can ensure the stability and longevity of the mold during the production process. Some machining errors will lead to mold welding, no matter how good the welding is, it is a loss to the mold; in addition, poor processing may affect the mold operation, reduce the mold life, and cause the mold to crack during the production process, even broken.

4. Standard parts

Although the standard parts are not directly involved in molding, they control the operation of the entire mold. Good standard parts should be wear-resistant, hard enough, high precision, and not easily deformed.

5. Touch(flying mold)

Touch is the experience of the mold fitter, seemingly simple work is the most technical content of the work. The flat mold is the simplest, and the fractal surface is basically ok as long as there is no flash break. It is very troublesome to use a car accessory mold. Not only is the fractal surface relatively irregular, but it often includes multiple sliders and top blocks. At the same time, through the touch, other problems of the mold can be improved and improved.