Aluminum is the most widely used metal material in non-ferrous metals, and its application range is still expanding. The use of aluminum to produce aluminum products is even more numerous and endless. According to statistics, there are more than 700,000 types. From the construction and decoration industry to the transportation and aerospace industries, different industries have different needs. Today I will introduce some surface treatments of aluminum products.

1. Sandblasting (shotblasting)

The process of cleaning and roughening the metal surface by the impact of high-speed sand flow.

The surface treatment of aluminum parts by this method can obtain a certain degree of cleanliness and different roughness of the surface of the workpiece, and improve the mechanical properties of the surface of the workpiece, thereby improving the fatigue resistance of the workpiece and increasing the distance between it and the coating. The adhesion has prolonged the durability of the coating film and is also conducive to the leveling and decoration of the coating.

2. Polishing

A process that uses mechanical, chemical, or electrochemical action to reduce the surface roughness of a workpiece to obtain a bright, flat surface. The polishing process is mainly divided into: mechanical polishing, chemical polishing, electrolytic polishing. The aluminum parts can be close to the stainless steel mirror effect after mechanical polishing + electrolytic polishing. This process gives us with a high-grade contracted, fashionable future feeling.

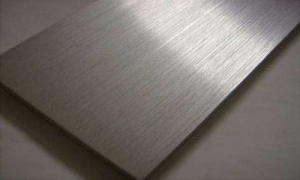

3. Brushing

Brushing is the manufacturing process of repeatedly scraping the aluminum plate out of the line with sandpaper. Brushing can be divided into straight brushing, random brushing, spiral brushing, thread brushing. The brushing process can clearly show each tiny silk mark, so that the metal matte has a fine hair shine, and the product has both fashion and technology sense.

4. High glosscutting

Using a carving machine, the diamond cutter is reinforced on the spindle of the carving machine that rotates at a high speed (typically 20,000 rpm) to cut parts, resulting in local highlight areas on the product surface. The brightness of the cutting highlight is affected by the speed of the milling drill. The faster the drill speed, the brighter the cutting highlight, otherwise it will be darker and easy to occur milling mark. High-gloss cutting is particularly used in mobile phones, such as the iPhone5. In recent years, some high-end televisions have adopted high-gloss milling technology on the metal frame. In addition, anodizing and wire drawing have made the whole TV full of fashion and technology.

5. Anodizing

Anodizing refers to the electrochemical oxidation of metals or alloys. Under the corresponding electrolyte and specific process conditions, aluminum and its alloys form an oxide film on aluminum products (anodes) due to the applied current. Anodizing can not only solve the defects of aluminum surface hardness and abrasion resistance, but also extend the service life of aluminum and enhance the aesthetics. And it has become an indispensable part of aluminum surface treatment and is the most widely used and very successful process.