A cavity filter is a type of radio frequency (RF) or microwave filter that is designed to selectively pass certain frequencies while attenuating or rejecting others. It is called a “cavity” filter because it consists of one or more resonant cavities that help achieve the desired filtering characteristics.

Here’s how a cavity filter works:

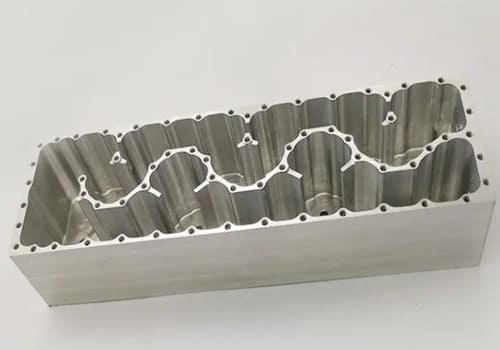

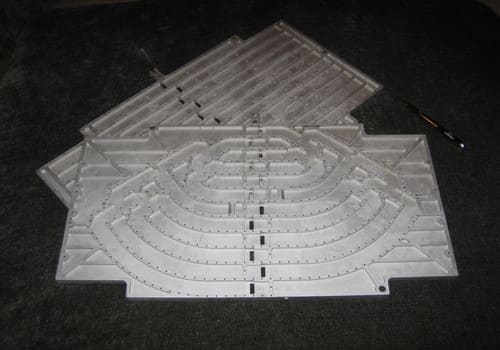

Resonant Cavities: The core of a cavity filter consists of one or more resonant cavities. These cavities are typically made of metal and are designed to resonate at a specific frequency or range of frequencies.

Input and Output Ports: The signal to be filtered is introduced into the cavity filter through input and output ports. The cavities are strategically placed in the signal path.

Frequency Selectivity: The resonant cavities are designed to resonate at the desired frequency or frequencies, allowing these specific frequencies to pass through the filter with minimal attenuation.

Rejection of Unwanted Frequencies: Frequencies that do not match the resonant frequency of the cavities are strongly attenuated or rejected. This rejection is a result of the cavity filter’s inherent impedance mismatch at those frequencies.

Tuning and Adjustment: Cavity filters can often be tuned and adjusted to achieve the desired filtering characteristics. This may involve changing the dimensions of the resonant cavities or adjusting the coupling between cavities.

To make a cavity filter, you need some understanding of RF and microwave circuit design and access to appropriate materials and tools.

Here’s a simplified overview of the steps involved:

Design the Filter: Determine the specific frequency or frequency range that you want to filter. This involves calculating the dimensions and characteristics of the resonant cavities, such as their dimensions, shape, and material properties.

Select Materials: Choose appropriate materials for constructing the resonant cavities. Typically, metals like aluminum or copper are used due to their good conductivity.

Fabrication: Fabricate the metal cavities to the designed specifications. This may involve machining, bending, and welding the metal to create the cavities. You may also need to include input and output connectors.

Assemble the Filter: Assemble the resonant cavities in the desired configuration, ensuring that they are properly spaced and aligned. Proper alignment and spacing are crucial for the filter’s performance.

Tuning: Once the filter is assembled, you may need to tune it to achieve the desired frequency response. This may involve adjusting the dimensions of the cavities or modifying the coupling between them.

Testing: Test the filter to verify its performance. You can use network analyzers or spectrum analyzers to measure its frequency response and attenuation characteristics.

Please note that designing and constructing cavity filters can be a complex task, and it is often performed by engineers and technicians with expertise in RF and microwave technology. If you’re not experienced in this field, it’s advisable to seek guidance or consult with professionals to design and build a cavity filter to meet your specific requirements.

Ready to create your own custom CNC Machining parts? Contact us today to learn more about our CNC machining services and get a quote tailored to your needs!