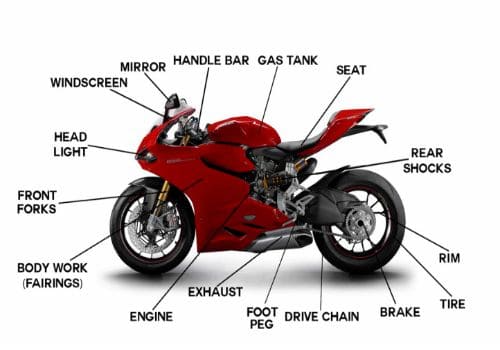

The metal parts of a motorcycle include the frame, engine, wheels, suspension system, brake system and other parts. Different metal parts use different materials and surface treatment processes according to functional requirements.

The following is a detailed introduction to some common metal parts, materials and surface treatment methods:

1. Frame

Material: Commonly used steel, aluminum alloy and carbon fiber.

Steel: High-strength steel (such as high-carbon steel, alloy steel) is often used in high-performance motorcycles.

Aluminum alloy: Aluminum alloy is often used for lightweight design, especially on sports motorcycles.

Electroplating: used for corrosion protection, common ones include chrome plating and zinc plating.

Spraying: Powder spraying or liquid spraying provides beauty and rust protection.

Anodizing: Aluminum alloy frames are often anodized to increase corrosion resistance and hardness.

2. Engine

Material: Mainly composed of aluminum alloy, steel alloy and iron alloy.

Aluminum alloy: The engine housing and cylinder block are usually made of aluminum alloy, which is light and has good heat dissipation performance.

Steel alloys: such as high carbon steel or alloy steel are used for internal engine parts (such as crankshafts, pistons, etc.) because of their wear resistance and high strength.

Cast iron: Some older or high-load engines still use cast iron materials, which have good wear resistance.

Surface treatment:

Anodizing: A common surface treatment method for aluminum alloy parts to enhance wear resistance and corrosion resistance.

Coating (such as ceramic coating): Special coatings (such as friction reduction coatings) are sometimes used inside the engine to improve wear resistance and heat dissipation.

Chrome plating: Some engine parts (such as valves and pistons) are chrome-plated to enhance corrosion resistance and wear resistance.

3. Wheels

Material: Aluminum alloy, magnesium alloy.

Aluminum alloy: Lightweight and has good strength, widely used in motorcycle wheels.

Magnesium alloy: High-end motorcycles use magnesium alloy wheels, which have extremely light weight and strong rigidity.

Surface treatment:

Anodizing: The surface of aluminum alloy wheels is often anodized to provide corrosion resistance.

Spraying: Spraying or heat treatment technology is often used for beautiful decoration and enhanced protection performance.

4. Suspension System

Material: Aluminum alloy, steel.

Aluminum alloy: Aluminum alloy is often used for the brackets and adjustment parts of the front and rear suspension.

Steel: Steel is often used for some metal parts in springs and shock absorbers.

Surface treatment:

Chrome plating: In order to prevent corrosion, especially the shock absorber piston rod, chrome plating is usually performed.

Spraying: Used for decoration and increased corrosion resistance.

5. Brake System

Material: Steel, aluminum alloy.

Aluminum alloy: Brake discs and brake calipers often use aluminum alloy materials.

Steel: Brake discs, brake lines and other parts may use high-strength steel.

Surface treatment:

Anodizing: Some brake calipers use anodizing to enhance corrosion resistance.

Spraying and electroplating: Brake discs and calipers sometimes use spraying or electroplating technology to increase beauty and extend durability.

6. Fuel Tank

Material: Steel, aluminum alloy, plastic.

Steel: Traditional fuel tanks are generally made of steel, which can withstand higher pressure and impact.

Aluminum alloy: In order to reduce weight, some high-end motorcycles use aluminum alloy fuel tanks.

Surface treatment:

Electroplated or sprayed: The surface of steel fuel tanks is often electroplated or sprayed to improve corrosion resistance and appearance.

Internal anti-corrosion coating: The inside of the fuel tank is often coated with an anti-corrosion coating to prevent corrosion caused by moisture and impurities in the oil.

7. Other parts

Handlebars, footrests, seat frames: These parts are usually made of aluminum alloy or steel.

Surface treatment:

Electroplated, sprayed: Improve appearance and increase corrosion resistance.

Anodizing: Especially for aluminum alloy parts, anodizing is often used.

Common metal surface treatment methods:

Electroplated (chrome plating, zinc plating, nickel plating): Provides anti-corrosion protection and glossy appearance.

Anodizing: Enhances the corrosion resistance and hardness of aluminum alloys.

Coating (spray painting, spray powder): Common surface treatment methods that have both anti-corrosion effects and improve appearance quality.

Laser marking or engraving: Used for customization and identification.

In summary, the metal parts of a motorcycle are usually made of a variety of metal materials, and different surface treatment technologies are used to achieve various effects such as aesthetics, corrosion resistance, enhanced strength, and improved wear resistance.

Ready to create your own custom CNC Machining parts? Contact us today to learn more about our CNC machining services and get a quote tailored to your needs!