In today’s competitive manufacturing landscape, choosing the right production method is key to balancing quality, efficiency, and cost. While traditional machining methods still hold value in some scenarios, CNC machining has emerged as a smarter and often more cost-effective alternative—especially for high-precision and repeatable parts.

In this article, we explore why CNC machining can be the more economical choice for your business and how it helps optimize both time and budget.

1. Faster Turnaround Time Reduces Labor Costs

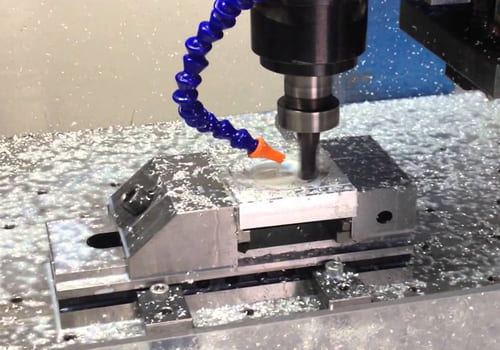

Traditional machining often requires manual intervention, setup, and supervision. In contrast, CNC (Computer Numerical Control) machines run autonomously once programmed, drastically reducing the time and labor needed to complete a part.

💡 Key Benefits:

-

Minimal manual handling

-

Simultaneous multi-axis operations

-

24/7 production with automation

Less labor time translates to lower overall manufacturing costs, especially for medium to large production volumes.

2. Higher Precision Means Less Waste

CNC machining delivers exceptional accuracy and repeatability. Unlike manual methods, CNC machines follow exact digital designs, minimizing material waste caused by human error or inaccurate cutting.

🎯 Result:

-

Fewer defective parts

-

Lower scrap rates

-

Reduced rework and quality control costs

Precision = profitability.

3. Scalability Without Sacrificing Quality

Whether you’re producing a single prototype or thousands of parts, CNC machining scales seamlessly. Traditional methods often require more setup and adjustment for each new batch, increasing time and cost.

With CNC:

-

Set it once, repeat with consistency

-

Programs are easily stored and reused

-

Ideal for batch production and on-demand manufacturing

This makes CNC machining a cost-effective solution for both low- and high-volume projects.

4. Less Tooling and Setup Costs Over Time

While initial CNC machine programming can take time, the long-term savings are significant. Traditional machining often requires custom jigs, fixtures, or manual adjustments for each part, increasing overhead.

With CNC:

-

One-time digital programming

-

Reusable designs

-

No need for extensive tooling or setup changes

The more parts you produce, the cheaper each unit becomes.

5. Reduced Downtime and Maintenance

Modern CNC machines are built for reliability and continuous operation. With proper maintenance, they experience less downtime than manual machines, which often depend on the operator’s skill and vigilance.

🛠 CNC Advantages:

-

Predictive maintenance alerts

-

Fewer moving manual components

-

Automated error detection

Fewer interruptions mean higher productivity and lower maintenance costs.

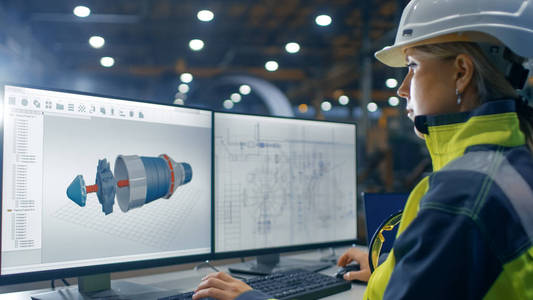

6. Integration With CAD/CAM Software Saves Engineering Time

CNC machining integrates directly with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, shortening the time between concept and production.

You don’t need to create multiple physical prototypes or drawings—just upload your design file, and production can begin.

🎨 Benefits:

-

Faster prototyping

-

Real-time simulation of part geometry

-

Design optimization for machining

Less time in the design-to-manufacture cycle = more savings.

7. Long-Term Cost Benefits for Custom Parts

For businesses that require custom, complex, or tight-tolerance components, CNC machining is often the only cost-effective solution. Traditional methods may not offer the same level of precision or efficiency without added costs.

At DO Machining, we specialize in helping clients reduce cost-per-part while maintaining high quality—no matter how complex the geometry or material.

Conclusion: CNC Machining is a Smart Investment

While the upfront cost of CNC machining may appear higher than traditional methods, the long-term savings in labor, waste, tooling, maintenance, and scalability make it a smart investment for any business looking to grow efficiently.

Whether you’re creating prototypes, custom parts, or full-scale production runs, CNC machining offers a better return on investment—in both time and money.

👉 Learn more about our CNC machining services at: https://www.domachining.com